Your Current Position: PRODUCTS

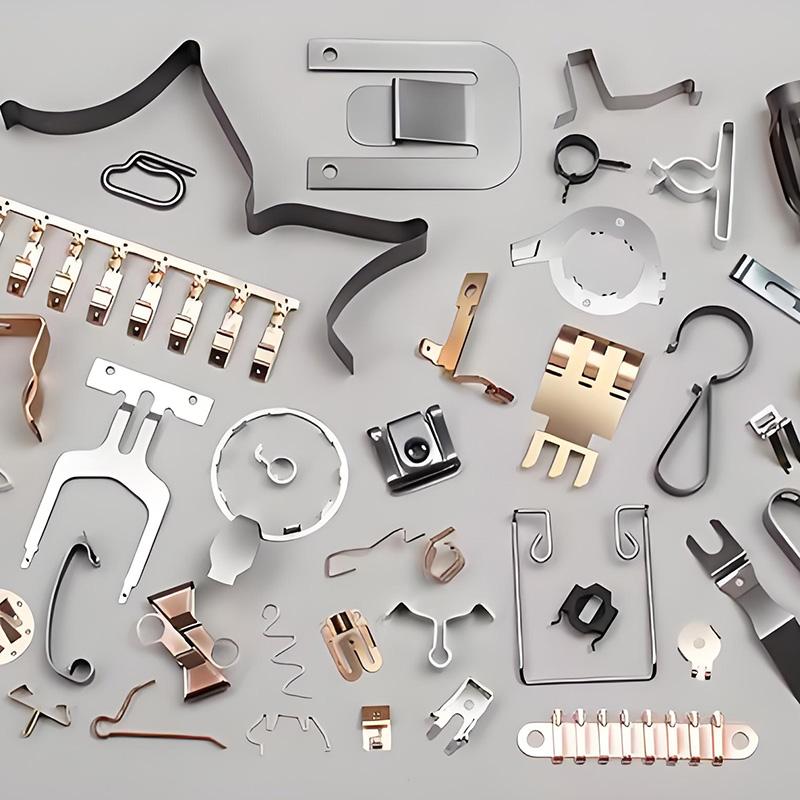

Ultra-Precision Micro-Stamping Die

We meticulously manufacture according to your 2D/3D drawings and tolerance specifications. From core cavities and mold bases to standard components like ejector pins and sliders, all parts are machined and assembled in-house, ensuring 100% fidelity to your design intent and a perfect fit for your product.

Turnkey Stamping Die System

We provide a comprehensive range of mold steel options, from domestic grades like P20/718 to imported steels such as ASSAB, DAC, and NAK80. We recommend the optimal material based on your production volume (e.g., <100K or >1M cycles) and product requirements (e.g., corrosion resistance, high gloss), ensuring the best balance of mold longevity and cost-effectiveness.

Your Premier Partner for End-to-End Precision Custom Molds

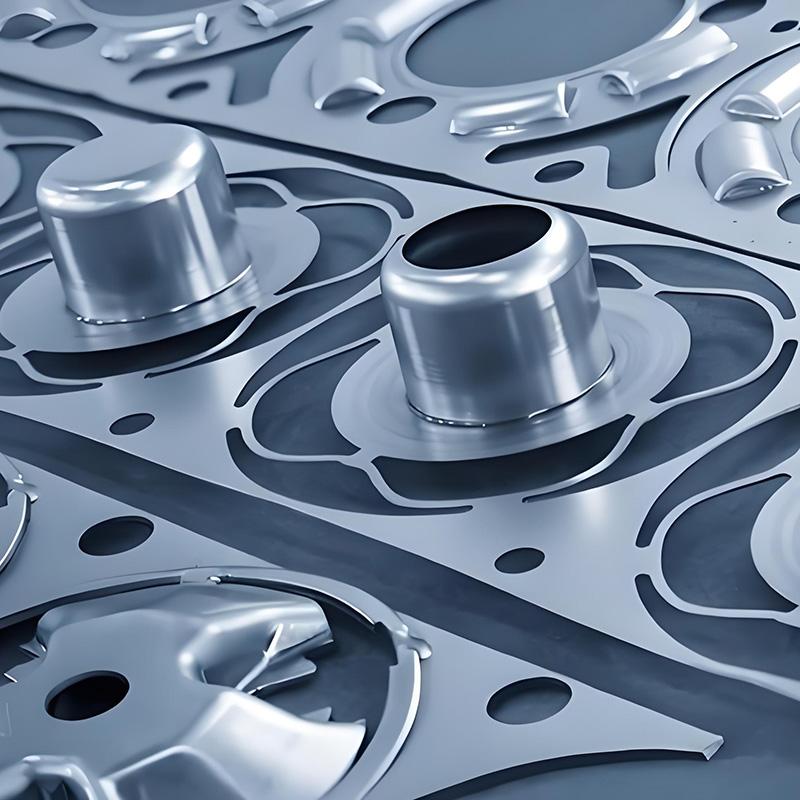

Our core value lies in integrating deep engineering expertise, advanced manufacturing technology, and customer-centric service. We operate our own modern workshop, equipped with high-precision machining centers, EDM machines, and inspection equipment from Germany and Japan. This ensures every step—from core/cavity machining to final assembly and debugging—is under stringent control.

Rapid Prototype Stamping Die

We specialize in consolidating multiple processes into a single mold. Whether it's internal/external thread demolding or gas-assisted molding for injection molds, or progressive stamping combining blanking, bending, and drawing, our precision engineering helps reduce production steps and boost efficiency.

Low-Volume, High-Mix Custom Die

Core component machining accuracy reaches ±0.002mm, with overall mold assembly precision within ±0.01mm. We provide CMM inspection reports for critical dimensions, guaranteeing your product's batch-to-batch consistency with quantifiable data.

Long-Life, Heavy-Duty Stamping Die

Equipped with high-speed milling and precision EDM machines, we offer swift mold modifications and insert replacements. We support small-batch trial runs and collaborate on process optimization (temperature, pressure, speed) until samples meet all specifications.

Cost-Optimized Stamping Solution

Molds can be pre-equipped with automation interfaces, such as robotic pick-up points, sensor mounting ports, and hot runner system bus interfaces, ensuring seamless integration into your smart production lines for automated operation.

High-Volume Production Die

As your source factory, we provide end-to-end support from design review and trial run monitoring to mass production maintenance, servicing guidance, and spare parts supply. We maintain complete technical archives, enabling rapid response to repair or replication needs, even years later.

Complex Geometry Forming Die

Final delivery includes not only the physical mold but also a complete technical documentation package (material certificates, heat treatment reports, precision inspection reports, assembly drawings, operation manual). We ensure compliance with your specified safety and industry standards (e.g., CE Machinery Directive, SPI standards).